COMPLETED DRAIN WATER HEAT RECOVERY COMMERCIAL, INDUSTRIAL AND INSTITUTIONAL PROJECTS

Commercial and institutional buildings are generally characterized by frequent and high volume usage of hot water that is literally poured down the drain. The ThermoDrain is designed to recover this wasted energy and transfer it directly back into your potable water heating system thereby significantly reducing the costs associated with hot water heating. Our dual wall construction heat exchanger is code approved for use with potable water.

COMPLETED DRAIN WATER HEAT RECOVERY COMMERCIAL, INDUSTRIAL AND INSTITUTIONAL PROJECTS

6 ThermoDrain TD480A3 series being used in a commercial laundry application

Laundry savings scenario using drain water heat recovery

High maintenance heat exchangers with filtration systems have been used for heat recovery in laundry systems. The ThermoDrain does not require maintenance and solids can flow freely through the ThermoDrain without the risk of blockage.Savings expected is 35%, ROI is 2-5 years.

Dishwasher scenario using drain water heat recovery

Through the use of ThermoDrain, the end result is a reduction in hot water load vary from 32% to 45%. Without ThermoDrain: We start with 100 units of gas, 20 units are lost to water heater exhaust, 80 unit are used by the dishwasher

With ThermoDrain: Energy required 40 units, 80 units are used by the dishwasher, (30 are supplied by the water heater and 50 are supplied by the ThermoDrain)

PDF- Engineering technical binder

Shower drain water heat recovery for sports centers

A sport center having 16 showers is operating at a combined total of 100 hours of shower time per week. Low flow shower heads of 1.6 gallon per minute operate at a shower temperature of 39°C (102°F). The natural gas heater is 78% efficient. The annual energy that is wasted down the drain is 272 GJ from the showers alone.

The potential for drain water heat energy recovery is calculated based on preheating the cold water going to the water heater using 4 ThermoDrain units. At an estimated 0.46$ per m3, the energy cost saving is 1905$/year with a 3.4 year payback.

PDF- Engineering technical binder

Water heating solutions for hotels

A hotel with 80 rooms is occupied at 70%. The average shower time per room is 20 minutes per day and standard flow shower heads are used at a shower temperature of 39°C (102°F). The natural gas heater is 78% efficient. The annual energy that is wasted down the drain is 583 GJ from the showers alone.

The potential for drain water heat energy recovery is calculated based on preheating the cold water going to the shower using one ThermoDrain unit for two adjacent rooms. At an estimated 0.46$ per m3, the energy cost saving is 2654$/year with a 6.8 year payback.

PDF- Engineering technical binder

Affordable housing complex with central heating scenario

A building having 24 housing units has central water heating. Three drain stacks service two units per floor each. Given the total shower time for each unit is 30 minutes per day and standard flow shower heads are used at a shower temperature of 39°C (102°F). The natural gas heater is 78% efficient. The annual energy that is wasted down the drain is 281 GJ from the showers alone.

The potential for drain water heat energy recovery is calculated based on preheating the cold water going to the water heater using two ThermoDrain unit per drain stack. At an estimated 0.46$ per m3, the energy cost saving is 1519$/year with a 3 year payback.

PDF- Engineering technical binder

Slab Construction

In the case where slab on grade construction or where the drain flow is in the floor, the drain water must be elevated using a pump.

Electrical consumption for pumping drain water is 1-2% of the ThermoDrain energy savings. This type of system is difficult but not impossible to retrofit.

Sustainable LEED Building Projects

The installation of a ThermoDrain is a simple, proven and efficient measure that will contribute in obtaining credits associated with energy efficient LEED projects. Several LEED projects are presently using ThermoDrain technology to reduce the energy required to heat water.

ThermoDrain Specification Sheets and

Drain water heat recovery engineering technical binder

The ThermoDrain is the latest technology in Drain Water Heat Recovery. Its unique design provides outstanding

savings that can be attributed to its superior performance and durability. With its exclusive features, the

ThermoDrain is simply the best technology available today!

PDF- Engineering technical binder

Drain water heat recovery savings calculator

You can compare different savings scenarios using this excel drain water heat recovery calculator.

A Unique Heat Exchange Technology

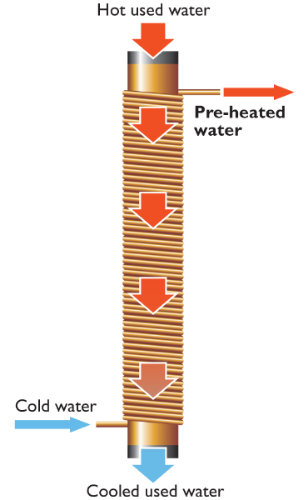

The ThermoDrain drain water heat recovery unit is composed of a copper drain section around which a copper pipe is moulded and wound. As hot water drains down the central copper pipe, an important heat transfer occurs thereby preheating the cold water circulating in the outer coil. This incoming cold water may be preheated by more than 18 degrees Celsius (32 degrees F) before entering the water heater.

What makes the ThermoDrain so unique is that it is the only style of heat exchanger that is allowed to be used for potable water due to its double wall leak-proof design.

The ThermoDrain is the only drain water heat recovery unit that has a very low-pressure drop through the use of a single 3/4″ coil. Other manufacture designs require splitting of the flow into 1/2″ or 3/8″ thin walled channels and headers. Designs that do not improve performance but may impact longevity of the unit.

ThermoDrain is manufactured using potable copper tubing with walls that are 0.045″ thick and a 0.75″ in diameter.

The ThermoDrain heat exchanger works under the principle of gravity film exchange. Due to the superficial tension present in liquids, the wastewater clings in a film-like fashion to the inside wall of the drain pipe as it undergoes gravity flow in the open drain. This greatly improves the effectiveness of heat transfer from the falling drain water to the water inside the copper coils that winds around the central pipe. The heat exchange is thus completed with no contamination risk to the incoming cold water.

A superficial film forms on the interior wall of the ThermoDrain as hot waste water transfers its heat energy to the copper drain tube.

The ThermoDrain, drain water heat recovery does not have drain restrictions such as fins or thin walls on the inside of the drain pipe. Clogging of the Thermodrain is not possible like other heat exchangers thus making it ideal for semi solids.

ThermoDrain drain water heat recovery exclusive PEX fittings